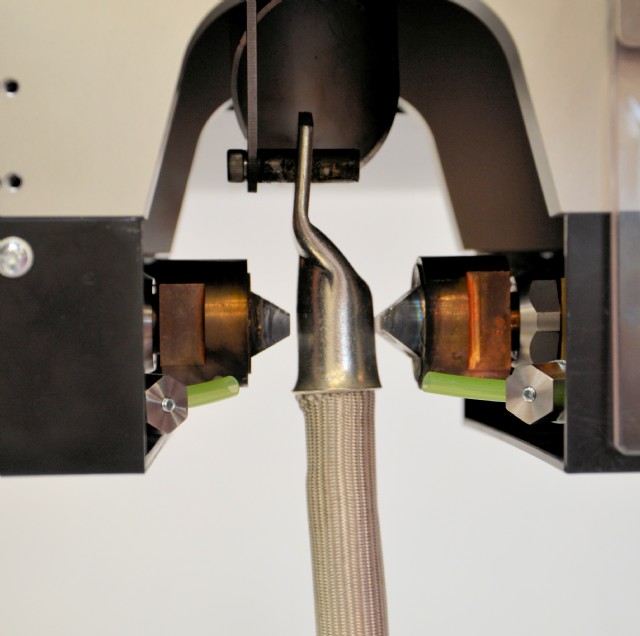

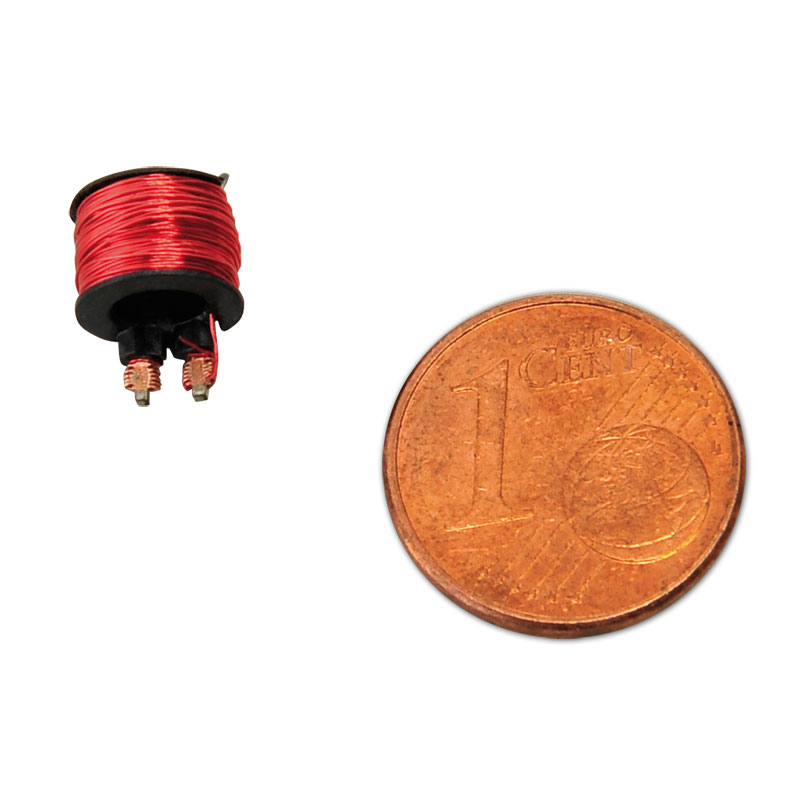

Using new and innovative technology can be risky, but it can often be rewarding. European electric-motor manufacturers Bosch, Siemens and Volkswagen realized this in 2011 after discovering hot crimping. For decades, these companies used machines or chemicals to strip the enamel coating off the ends of magnet wires before crimping them to copper ring terminals or sleeves. Hot crimping, in contrast, vaporizes the insulation during crimping of the wire and terminal or sleeve. By eliminating the stripping step, hot crimping enables manufacturers to increase productivity. . . .

Hot crimping technology features specially designed welding heads that quickly attach terminals to wire from 30 AWG to 350 MCM.

Hot Crimping AMADA WELD TECH

US11031242B2 - Methods for depositing a boron doped silicon

Hot Crimping AMADA WELD TECH

CrimPro Crimper for Wire Ferrules AWG 2-4-6.

Pro'sKit 902-160 CrimPro Crimper for Wire Ferrules, AWG 2-4-6, Multi

Hot crimping Connection of wires with cable lugs

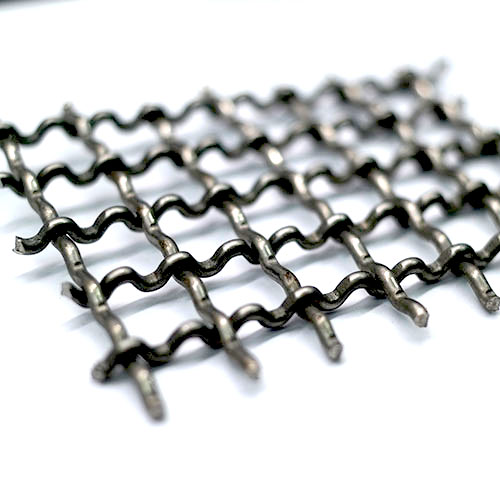

PROCESS HOT CRIMPING WINDING WIRES

BEKMLOD 10Pcs U Shaped Thick Copper Crimping Terminal Connector

Hot Crimping for Joining Magnet Wires, 2012-04-02

PROCESS HOT CRIMPING WINDING WIRES

USD947913S1 - Susceptor shaft - Google Patents

Hot crimping Connection of wires with cable lugs

US10249524B2 - Cassette holder assembly for a substrate cassette

US11069510B2 - Substrate processing apparatus - Google Patents

US11168395B2 - Temperature-controlled flange and reactor system

Terminal Hot Crimping Machine for Magnet Wires