Download scientific diagram | Processing times for the cargo hold, top-side tank and fore-peak tank datasets: (Left) histogram; (Right) processing time versus percentage of defective area in the image. from publication: Vision-Based Corrosion Detection Assisted by a Micro-Aerial Vehicle in a Vessel Inspection Application | Vessel maintenance requires periodic visual inspection of the hull in order to detect typical defective situations of steel structures such as, among others, coating breakdown and corrosion. These inspections are typically performed by well-trained surveyors at great cost | Corrosion, Artificial Neural Network and Unmanned Aerial Vehicles | ResearchGate, the professional network for scientists.

Distribution of heavy cargo in holds and water ballast distribution for bulk carriers

OIL TANKER OPERATIONS (Loading) - Conventional Tanker Basics

M4 Sherman - Wikipedia

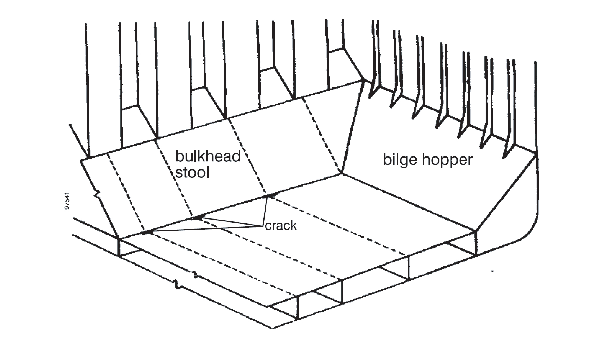

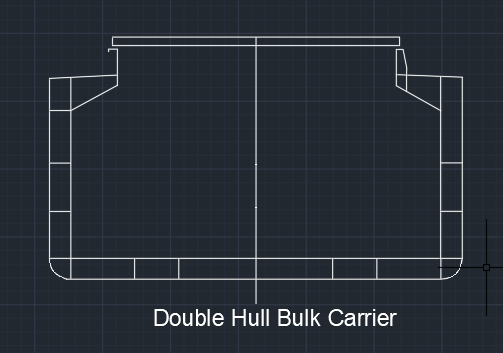

Deterioration of bulk carriers hull and consequences of hull damage /forward flooding

The Climate Crisis Gives Sailing Ships a Second Wind

PDF) Vision-Based Corrosion Detection Assisted by a Micro-Aerial Vehicle in a Vessel Inspection Application

Processing times for the cargo hold, top-side tank and fore-peak tank

6.2 Cargo Holds

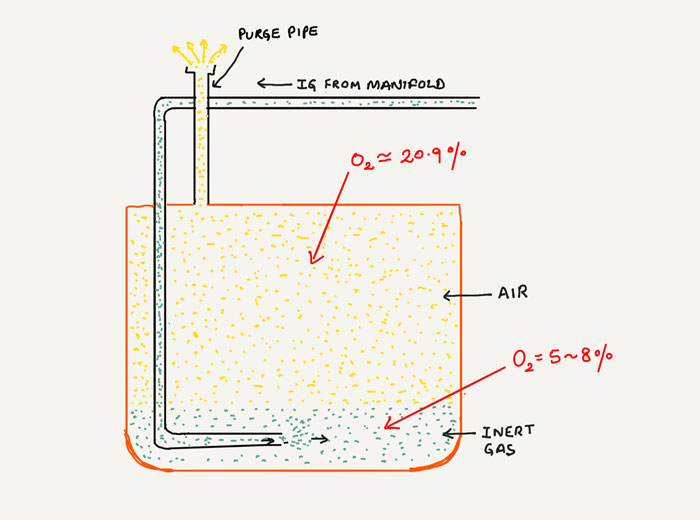

Inerting of Cargo Tanks: How Exactly to do it? - MySeaTime

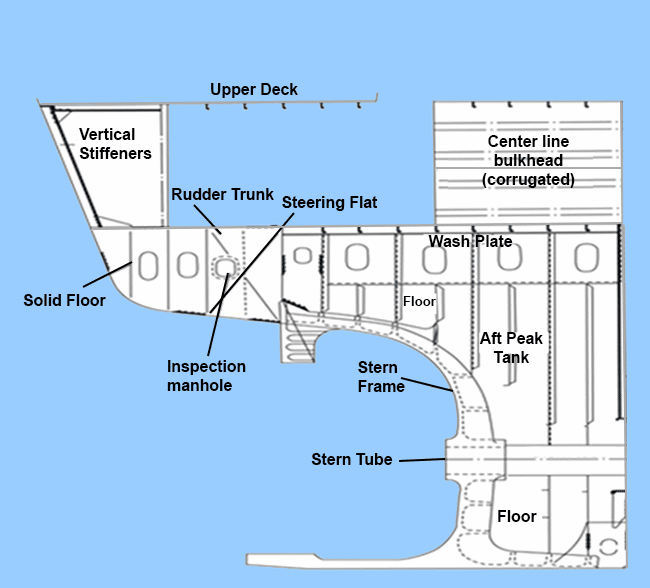

Design Of Cargo Holds In Different Types Of Ships